Our pellets

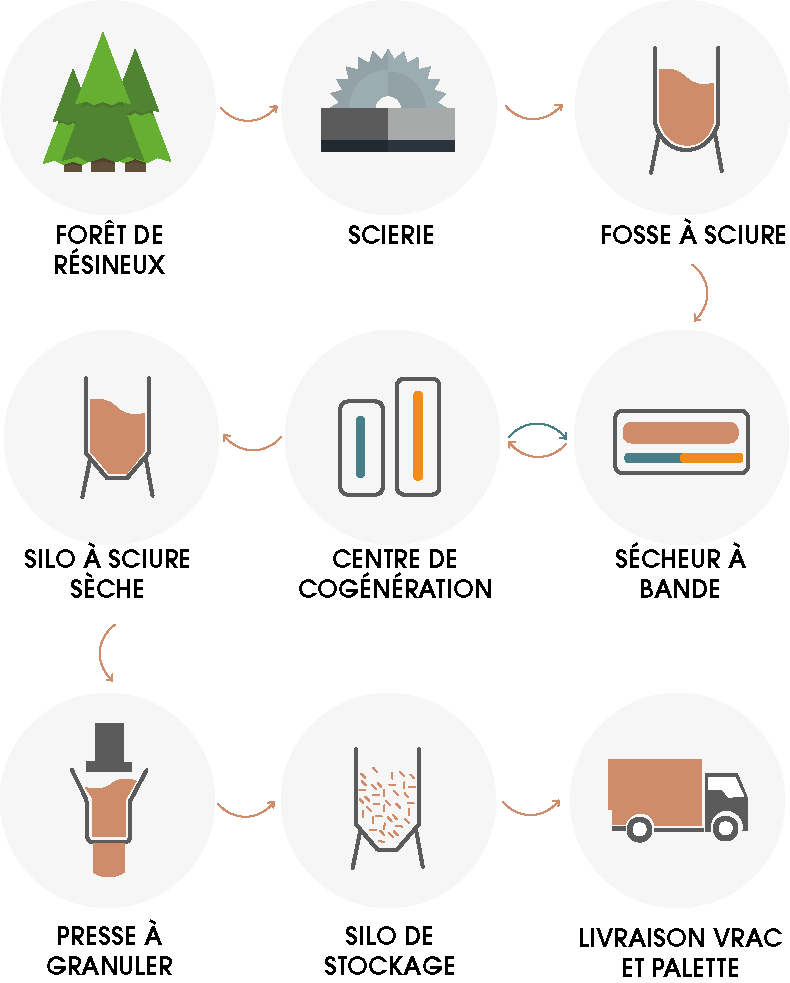

Pellet production in 4 stages

Our wood pellet production process begins with the innovative drying of sawdust in our thermo-electric power station, reducing our carbon footprint. Next, the sawdust is transformed into pure pellets using high-performance presses and rigorous quality control. Finally, the pellets are automatically packed into ready-to-use 15 kg bags, which are available for sale at several points in France, with the option of pallet delivery.

Step 1 : sawdust drying

We use advanced German and Austrian technologies in our thermoelectric plant to naturally dry the sawdust. By utilizing excess steam, we ensure uniform and efficient drying of the raw material.

Step 2 : transforming sawdust into wood pellets

The transformation of dry sawdust into wood pellets is achieved with our 3 high-performance

CPM presses, each capable of producing 5 tons per hour.

Compression Process

Sawdust is hot-pressed to form cylindrical pellets

Quality Assurance

Laboratory analyzes every 3 hours to ensure quality

100% Natural and Softwood

No binders or adhesives, guaranteeing product purity

Step 3 : packaging wood pellets

Our packaging process is fully automated, using a bagging machine, palletizer, and stretch wrapper to ensure a ready-to-use product.

Step 4 : where to buy our wood pellets

Moulin Bois Energie offers direct sales of wood pellet bags at several locations across France.

Here’s how you can purchase:

Sale of granules

Bagged Pellets Our 15 kg bags are available for purchase, primarily for pellet stoves and inserts. Each pallet contains 65 bags, totaling 975 kg per pallet. You can pick up your orders at one of the following locations:

Pallet Delivery

We also offer pallet delivery for added convenience. Here are the dimensions of our pallets: